-

Welcome to this forum . We are a worldwide group with a common interest in Birmingham and its history. While here, please follow a few simple rules. We ask that you respect other members, thank those who have helped you and please keep your contributions on-topic with the thread.

We do hope you enjoy your visit. BHF Admin Team

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bellis and Morcom

- Thread starter jennyann

- Start date

mw0njm.

A Brummie Dude

thanks lyn

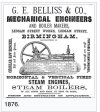

Belliss & Morcom

Claybrook Drive, Washford Industrial Estate

Redditch

Worcestershire

B98 0DS

Compressed Air Products & Services

www.reavell.com/belliss-and-morcom.aspx

Maurice Edwards

New Member

MauriceView attachment 150042My Dad worked at Belliss and Morcom from 1916 to 1923. as an apprentice. They built engines and they were not allowed to know what the engines were for. It turned out they were building 1st world war tank engines. Rules were very strict. If you were over 1minute late you were shut out and lost a days pay. My day wanted a day of leave for a very important reason but the management would not permit it. I have the refusal letter.

Last edited:

Brookfields Lad

master brummie

Maurice

What a fantastic picture. I drove past there last week and sadly the whole site is now high-rise blocks of apartments/offices under construction.

Richard Dye

master brummie

Welcome to the Forum Maurice, enjoy!Maurice

Hi my name is Richard Downing and my father Albert Downing worked for Belliss and Morcom as a center lathe worker turning very big crankshafts for ships.

when I was about 20 years old in 1964 I was working for Crockett and Lowe and was sent to Belliss and Morcom a couple of times to mount two very heavy metal patterns onto cast iron plates with wheels on them, very heavy duty equipment, I was not allowed to do any work myself, I could only tell other workers there what I needed done, the different working bays there were massive, one shaping machine table was big enough to park a double decker bus on it !!!!

In about 1971 I was on a ferry from Iona to Fionnphort ? Scotland and it had a Belliss and Morcom engine, because I remember reading the companies cast iron name plate on it. All the best.

when I was about 20 years old in 1964 I was working for Crockett and Lowe and was sent to Belliss and Morcom a couple of times to mount two very heavy metal patterns onto cast iron plates with wheels on them, very heavy duty equipment, I was not allowed to do any work myself, I could only tell other workers there what I needed done, the different working bays there were massive, one shaping machine table was big enough to park a double decker bus on it !!!!

In about 1971 I was on a ferry from Iona to Fionnphort ? Scotland and it had a Belliss and Morcom engine, because I remember reading the companies cast iron name plate on it. All the best.

Maurice Edwards

New Member

Hi My name is Maurice Edwards. My Dad was apprenticed at Bellis and Morcom from 1916 to 1923. During that time they built engines but were not allowed to know what they were for. It turned out thy were First World War tank engines. He didn't talk a lot about his time there but apparently they were very strict on time keeping then so if you were one minute late you got locked out. At one point he wanted a day off but permission was not granted (may have been due to the war effort). I have the letter. I wish I had asked a lot more questions about his time there. I have one photo of a group of them during a break. After his time at Belliss and Morcom he started a garage business in School Lane Yardley (where he lived all his life). Very near to St Edburghas church. After he died in 1959 my mother sold the business in 1963 and it has changed hans about 4 times since then. The original building with its belfast roof (typical of industrial buildings of the time) has been demolished and replaced.Hi my name is Richard Downing and my father Albert Downing worked for Belliss and Morcom as a center lathe worker turning very big crankshafts for ships.

when I was about 20 years old in 1964 I was working for Crockett and Lowe and was sent to Belliss and Morcom a couple of times to mount two very heavy metal patterns onto cast iron plates with wheels on them, very heavy duty equipment, I was not allowed to do any work myself, I could only tell other workers there what I needed done, the different working bays there were massive, one shaping machine table was big enough to park a double decker bus on it !!!!

In about 1971 I was on a ferry from Iona to Fionnphort ? Scotland and it had a Belliss and Morcom engine, because I remember reading the companies cast iron name plate on it. All the best.

All the best

Pedrocut

Master Barmmie

History of Technology, Charles Singer… (The Stationery Steam Engine, 1830-1900)

“The more usual type of high-speed vertical engine was, however, double-acting; for small powers it was made well into the twentieth century. One of the most successful manufacturers was G. E. Belliss of Birmingham especially when he applied the new system of forced lubrication, patented in 1890 by A. C. Pain, a designer on his staff, to the main moving parts. Previously, if the speed of double-acting engines was raised, very close adjustment of bearings was essential for quiet running. Owing to the expansion when hot exceeding the clearance when cold, crank pins and bearings were liable to seize as the temperature rose, resulting in serious damage. Forced lubrication made possible the successful running of double-acting engines at high speed without the risk of excessive wear and knocking. The system was, in fact, subsequently applied to practically all engines, turbines, and other high-speed machinery….”

“The more usual type of high-speed vertical engine was, however, double-acting; for small powers it was made well into the twentieth century. One of the most successful manufacturers was G. E. Belliss of Birmingham especially when he applied the new system of forced lubrication, patented in 1890 by A. C. Pain, a designer on his staff, to the main moving parts. Previously, if the speed of double-acting engines was raised, very close adjustment of bearings was essential for quiet running. Owing to the expansion when hot exceeding the clearance when cold, crank pins and bearings were liable to seize as the temperature rose, resulting in serious damage. Forced lubrication made possible the successful running of double-acting engines at high speed without the risk of excessive wear and knocking. The system was, in fact, subsequently applied to practically all engines, turbines, and other high-speed machinery….”

Hi nickap

Welcpme to Birmingham History Forum. There is already a Belliss and Morcom thread here.

Belliss and Morcom are still operating in Reddich

Welcpme to Birmingham History Forum. There is already a Belliss and Morcom thread here.

Belliss and Morcom are still operating in Reddich

You may have noticed that I am trying to find some records of my Grandfather's apprenticeship time at Bellis & Morcom from 1906 to 1912 approximately after which he emigrated to Australia. We often wondered where the name 'Quinton' came from as he named each of the houses the family lived in - 'Quinton'. So now we know. Thank you Weoley for that information. BevleyI grew up right alongside Bellis & Morcom's old sports ground and social club off Highfield Lane in Quinton, right at the back of Four Dwellings School, sandwiched between that and the Quinton Expressway. It was a big old white wooden building where we used to go to their children's Christmas party. It dated back before WW2, but I don't know how long before that. Everything else around there was built afterwards. I could watch the football teams play from our side window. By the time we moved in, in 1972, the old tennis courts there were already out of use and derelict, and the club had seen better days. When it was new it must have had lovely country views across to Clent, before they built the M5 and the woodgate valley estate.

The place was demolished about twenty years ago, and a load of houses stand there now.

Phillip2404

New Member

Hello, just looking at Belliss and Morcom information, my father, grandfather and great grand father also worked at the plant, and I also went in to engineering at Barr and Stroud near Glasgow. I am trying to track down any information about Albert Charles Pain 1890 ish. Regards, PhillipHi my name is Richard Downing and my father Albert Downing worked for Belliss and Morcom as a center lathe worker turning very big crankshafts for ships.

when I was about 20 years old in 1964 I was working for Crockett and Lowe and was sent to Belliss and Morcom a couple of times to mount two very heavy metal patterns onto cast iron plates with wheels on them, very heavy duty equipment, I was not allowed to do any work myself, I could only tell other workers there what I needed done, the different working bays there were massive, one shaping machine table was big enough to park a double decker bus on it !!!!

In about 1971 I was on a ferry from Iona to Fionnphort ? Scotland and it had a Belliss and Morcom engine, because I remember reading the companies cast iron name plate on it. All the best.

Phillip2404

New Member

Thanks for that info, need to do more research on the family tree, any more info welcone

regards, Phillip Pain

regards, Phillip Pain

Hi Richard Downing, I am sure I remember your father from my apprentice days at Belliss's MD (Main Depot) Icknield Square. He was a turner in the Machine Shop, right hand side under the No 2 Machine Gallery. He finished machined crankshafts for the steam engines, a highly skilled and very responsible craft. He was the only turner that I ever saw do this finish work and I was very impressed. As I remember he was always very smartly dressed I think he always wore a tie. Very unusual and made him stand out.Hi my name is Richard Downing and my father Albert Downing worked for Belliss and Morcom as a center lathe worker turning very big crankshafts for ships.

when I was about 20 years old in 1964 I was working for Crockett and Lowe and was sent to Belliss and Morcom a couple of times to mount two very heavy metal patterns onto cast iron plates with wheels on them, very heavy duty equipment, I was not allowed to do any work myself, I could only tell other workers there what I needed done, the different working bays there were massive, one shaping machine table was big enough to park a double decker bus on it !!!!

In about 1971 I was on a ferry from Iona to Fionnphort ? Scotland and it had a Belliss and Morcom engine, because I remember reading the companies cast iron name plate on it. All the best.

Richard Dye

master brummie

Crankshaft turners in those days was a very trusted position!Hi Richard Downing, I am sure I remember your father from my apprentice days at Belliss's MD (Main Depot) Icknield Square. He was a turner in the Machine Shop, right hand side under the No 2 Machine Gallery. He finished machined crankshafts for the steam engines, a highly skilled and very responsible craft. He was the only turner that I ever saw do this finish work and I was very impressed. As I remember he was always very smartly dressed I think he always wore a tie. Very unusual and made him stand out.

I found a medal belonging to my grandad, one side reads "Belliss & Morcom Recreation Club", the other "Dept Cricket Shield Winners 1935 S. J. Harris". He lived nearby but I didn't know he had been an employee. The link* the OP gave mentioned staff cards, are these searchable somewhere now?

Cheers all!

*updated link https://www.birminghammail.co.uk/news/local-news/history-of-wartime-factory-uncovered-46724

Cheers all!

*updated link https://www.birminghammail.co.uk/news/local-news/history-of-wartime-factory-uncovered-46724

Attachments

Last edited:

Richard Dye

master brummie

Welcome to The Forum A North, a really fine place, great folks and information, enjoy!I found a medal belonging to my grandad, one side reads "Belliss & Morcom Recreation Club", the other "Dept Cricket Shield Winners 1935 S. J. Harris". He lived nearby but I didn't know he had been an employee. The link* the OP gave mentioned staff cards, are these searchable somewhere now?

Cheers all!

*updated link https://www.birminghammail.co.uk/news/local-news/history-of-wartime-factory-uncovered-46724