A steam boiler pressure test, often a hydrostatic test, verifies the boiler's structural integrity and safety. It involves filling the boiler with water and raising the pressure to 1.5 times the working pressure, checking for leaks or weaknesses. This is a crucial safety measure, especially for older or repaired boilers

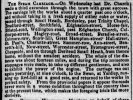

sadly lives were lost for shody workmanship and poor materials

n 1840, pressure tests on boilers were likely less rigorous and standardized compared to modern practices, but the basic principle remained the same: verifying the boiler's structural integrity under pressure. These tests likely involved observing the boiler's behavior under pressure, looking for leaks or signs of weakness.

Here's a more detailed look at boiler pressure testing in the 1840s:

1. The Goal: The primary purpose was to ensure the boiler could safely generate steam without busting

2. Methods: The testing methods would have been less sophisticated than today's hydrostatic testing, which involves pressurizing the boiler with water to a specific pressure. In 1840, they might have relied on observing the boiler's response to steam pressure, looking for signs of leaks, bulging, or other structural issues.

3. Materials: Boilers in the 1840s were typically made of cast iron or riveted iron plates, which had their own inherent limitations and potential weaknesses.

4. Safety: Safety was a primary concern, especially given the potential for catastrophic failures.

5. Standards: There were likely few, if any, standardized boiler codes or regulations in 1840. Safety would have been based on the knowledge and experience of the boiler makers and operators.

In summary: While the specifics of pressure testing in 1840 might be difficult to reconstruct precisely, the fundamental goal of ensuring boiler safety under pressure was certainly present. The methods would have been more rudimentary compared to modern practices, relying more on observation and experience.