It should be noted that there was another Arkinstall Bros in Great Hampton St, silver and silver plate manufacturers.

The business was started by David & Francis Arkinstall, sons of a retail brewer , John Arkinstall, in Cross St, West Bromwich. Francis was about 12 years older than David. Both worked as Roll turners in an iron mill, but the older Francis became a master galvanizer and about 1879 joined with his brother to form a galvanizing business, Arkinstall Bros, at 16 Milk St in premises that previously had been the business of Benjamin Parkes, wire fender maker. By the time of the 1882 Kellys directory they seem to have expanded to include no 17 Milk St also. The works would seem to be area in red on the mid 1880s map below, though it is possible that the works also included some adjoining areas in addition.

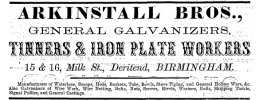

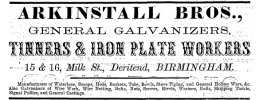

They were advertising in Kellys in 1882 as below. Apparently Waterloos were a brand of cast iron toilet cisterns much used at that time. I wish I could go back a check if in my childhood house had the label Waterloo cast into it.

From the late 1880s they also occupied premises at 38 Coventry St. Numbers 38,39,40 had previously been the home of The Priory Brass Co, and it is not clear how much of the premises were occupied. The Priory Brass factory is shown in red on this mid 1880s map

Around the late 1890s the firm strongly promoted an early fuel saving measure, "The Cinder sifter and Dustbin" aimed to ensure no waste of potential cinders from the fire;

The firm relinquished the Milk St site around 1907 and work was concentrated on the Coventry St one.

In 1920 Arkinstall Bros. was made into a limited company , and at the same time a new company Keep's Construction Ltd, wholly owned by the two brothers, was formed to take over the tank and iron plate business of Keep & Co in Barn St. The firm gave up the Coventry St site in 2007, and concentrated all work on the Barn Road site

Here are photos, presumably from around the 1920s of work inside the Coventry Road factory

and lorries in that period and later outside .

and here is the Coventry St entrance at about the end of the firm's occupation of the site

The Coventry St factory is still (or was in 2020) still there, unoccupied, looking rather the worse for ware

The business was started by David & Francis Arkinstall, sons of a retail brewer , John Arkinstall, in Cross St, West Bromwich. Francis was about 12 years older than David. Both worked as Roll turners in an iron mill, but the older Francis became a master galvanizer and about 1879 joined with his brother to form a galvanizing business, Arkinstall Bros, at 16 Milk St in premises that previously had been the business of Benjamin Parkes, wire fender maker. By the time of the 1882 Kellys directory they seem to have expanded to include no 17 Milk St also. The works would seem to be area in red on the mid 1880s map below, though it is possible that the works also included some adjoining areas in addition.

They were advertising in Kellys in 1882 as below. Apparently Waterloos were a brand of cast iron toilet cisterns much used at that time. I wish I could go back a check if in my childhood house had the label Waterloo cast into it.

From the late 1880s they also occupied premises at 38 Coventry St. Numbers 38,39,40 had previously been the home of The Priory Brass Co, and it is not clear how much of the premises were occupied. The Priory Brass factory is shown in red on this mid 1880s map

Around the late 1890s the firm strongly promoted an early fuel saving measure, "The Cinder sifter and Dustbin" aimed to ensure no waste of potential cinders from the fire;

The firm relinquished the Milk St site around 1907 and work was concentrated on the Coventry St one.

In 1920 Arkinstall Bros. was made into a limited company , and at the same time a new company Keep's Construction Ltd, wholly owned by the two brothers, was formed to take over the tank and iron plate business of Keep & Co in Barn St. The firm gave up the Coventry St site in 2007, and concentrated all work on the Barn Road site

Here are photos, presumably from around the 1920s of work inside the Coventry Road factory

and lorries in that period and later outside .

and here is the Coventry St entrance at about the end of the firm's occupation of the site

The Coventry St factory is still (or was in 2020) still there, unoccupied, looking rather the worse for ware